Abstract

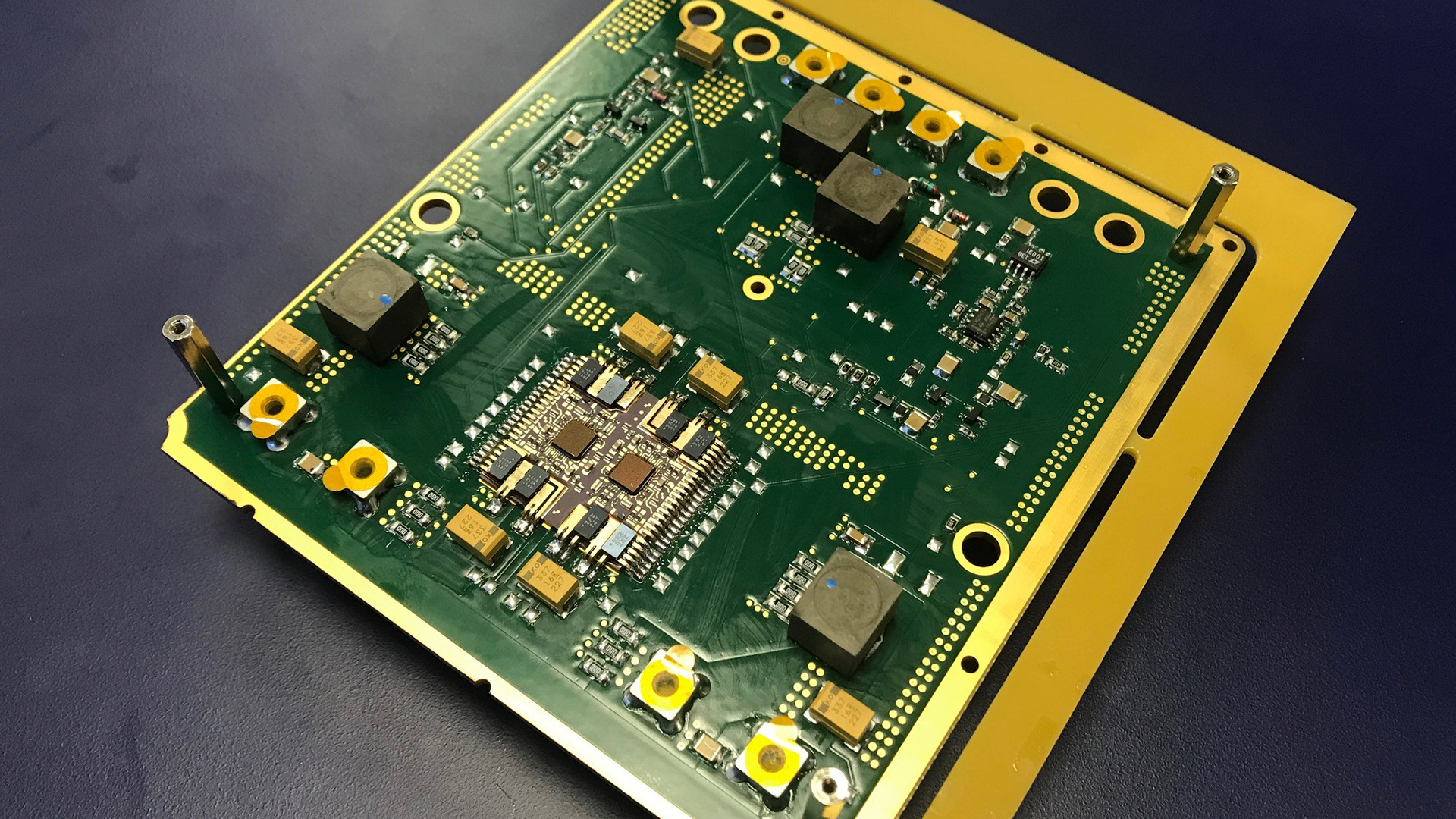

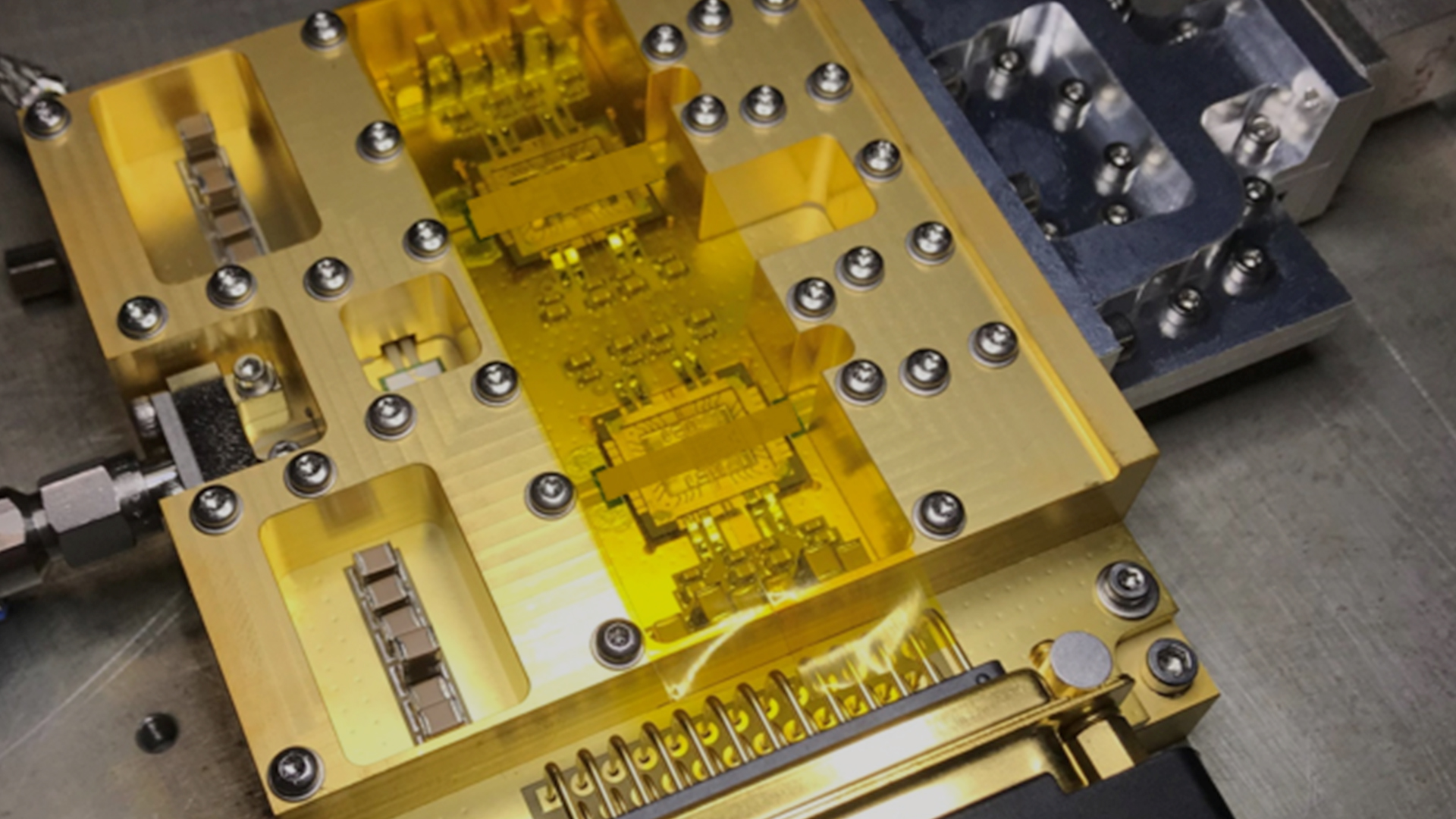

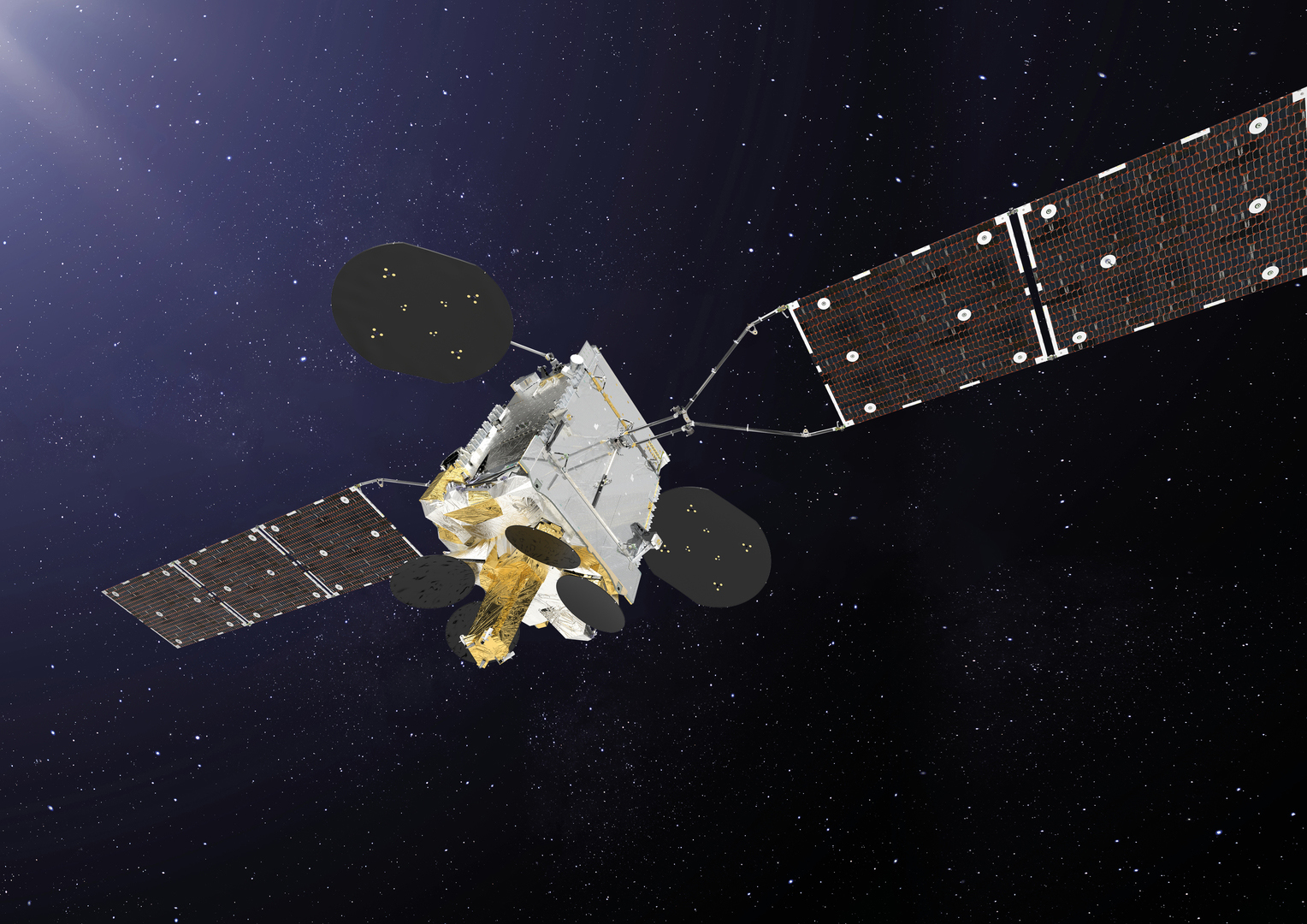

Reducing size and increasing power capabilities of electronic devices is of major importance for the overall performance of any satellite. Higher strength of the signals for Navigation applications and higher throughput in telecommunication satellites are pushing towards higher power density at payload subsystems. Currently there is a large maturity gap between GaN or Silicon Carbide components and thermal management solutions at assembly or package level. Most of available packaging solutions are from Japan or the US only, and not necessarily suitable for space applications in terms of reliability and/or performance.

What is HEATPACK

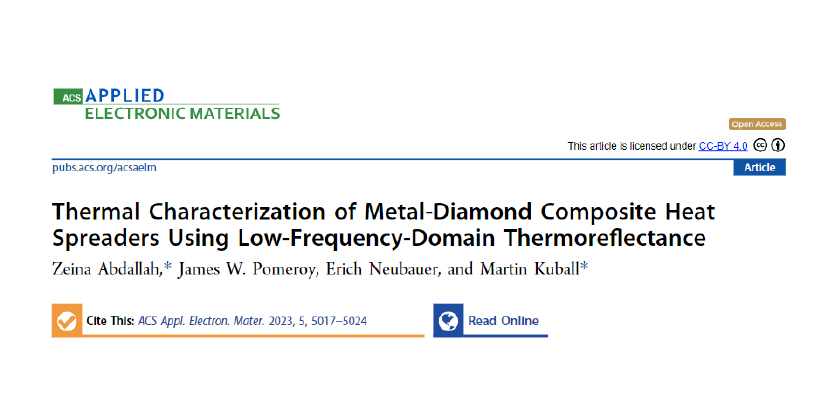

Is the European effort to develop the next generation of low thermal resistance packages, in particular thanks to the implementation of state-of-the-art diamond based composite materials and disruptive new heat sinking solutions. In order to secure a supply chain for packages and ensure the non‐dependence and competitiveness at European level, 9 partners from 7 different countries collaborate in HEATPACK. Space level reliability of the developed solutions as well as their commercial viability was demonstrated within the frame of the project. Now the consortium pushes the developed solutions into the market to address industries thermal dissipation challenges.

100

%Best practices

24

participants

328

person months

4

Years of Service

Latest News

“This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 821963”