Abstract / Introduction

High thErmAl efficiency componenTs PACKages for space: Reducing size and increasing power capabilities of electronic devices is of major importance for the overall performance of any satellite. In Navigation applications, increasing power and strength of signals is a key for improving accuracy and services of Global Navigation Satellite Systems (GNSS).

In Telecommunication industry, the space market is more and more challenged and its response towards always greater competitive solutions is aiming at High / Very High Throughput Satellites (HTS/VHTS), offering significant growth in satellite capacity and lower Gbps prices, foreseeing a more and more common increase of the temperature of core equipment. Consequently, several payload subsystems are facing thermal management constraints in direct relation with increasing power.

These high levels of heat flux density raise concerns about modules and components reliability and lifetime. To avoid failures occurring in electronic components1 (55% of which are caused by high temperature), it is of critical importance to have packaging technologies available, which can transport the generated heat to the surrounding environment and keep the temperature of the device within its specified limits.

Besides reliability concerns that still need to be addressed specifically for space use (contaminations, mechanical aggressions, radiations…), package thermal resistance needs to be significantly reduced beyond current state-of-the-art if the performance advantages obtained at semiconductor chip die level, arising from new technology developments such as of Gallium Nitride (GaN) components, are to be maintained at its highest, and also for being able to minimize volume and weight at module and equipment level.

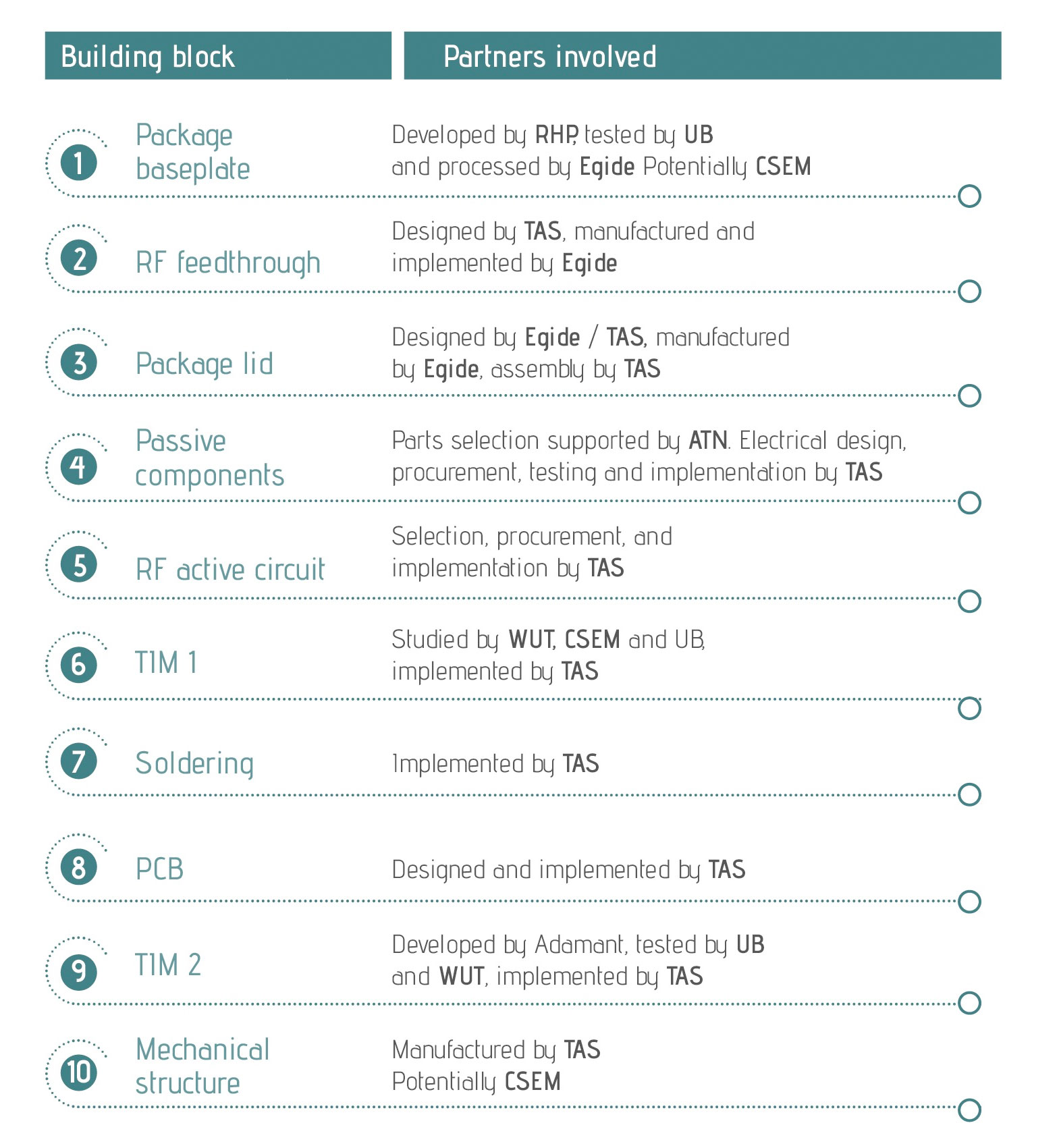

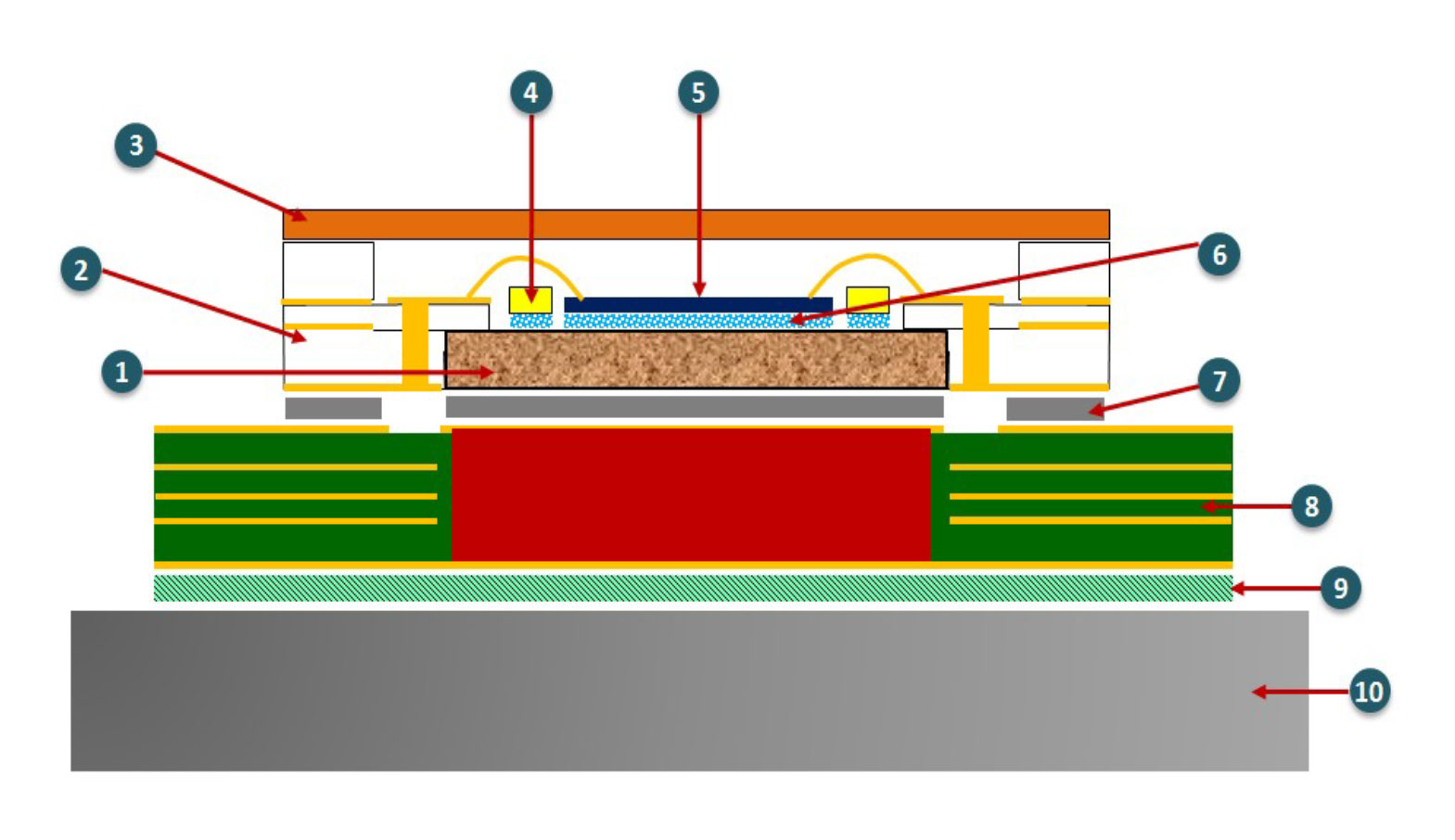

At this time in Europe, there is a large maturity gap between GaN or Silicon Carbide (SiC) components and thermal management solutions at assembly or package level. Most of available packaging solutions are from Japan or the US only, and not necessarily suitable for space applications in terms of reliability and/or performance. At European level, considerable progress has been lately made: the research and development work carried out in recent years has resulted in highly competitive solutions for next generation low thermal resistance packages. As an example, and strong predecessor to this project, very promising results came out of the EC funded AGAPAC FP7 Space project, with the realization of a highly dissipative package consisting of a diamond based composite baseplate (Figure 1).